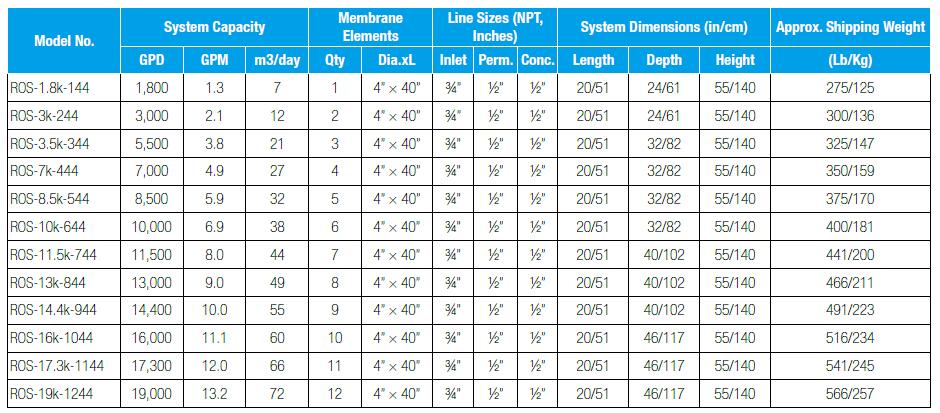

TWRO SYSTEM, Rogen/ ROS - COMMERCIAL Reverse Osmosis System/ 1,800~18,000GPD

These reverse osmosis systems use the proven, reliable components and are mounted on a sturdy stainless steel frame skid. There are numerous design details learned from years of experience that are incorporated in our water filtration systems. Our process and fluid design ensures an optimum membrane life and minimizes the membrane fouling.

Standard Features |

Available Options |

• 4" TFC spiral wound membranes

• Heavy duty high pressure tubing

• Low pressure switch

• Product and reject flow meters

• Electric inlet solenoid valve

• Pretreatment lockout

• Factory tested

• Pre/post filter and pump pressure gauges

• Powder coated carbon steel frame

• Corrosion resistant high pressure pump

• FRP/SS pressure vessel

• Tagging and identification of instrumentation

• Heavy duty 5 micron cartridge pre-filter |

• Automatic flush

• Pre piped skid system

• Blending: feed/product

• Tank float switch

• Recycle flow meter

• Post DI polishers

• Water softeners

• Ozonation system / UV sterilizers

• Media filters

• pH or ORP meter

• High pressure switch

• Export wood crating |

The ideal applications for brackish reverse osmosis systems include:

Metal Finishing

Beverage Production and

Bottled Water

Electronics

Pharmaceutical

Mining Industry

Chemical Blending |

Safe Drinking Water

Rinse Water

Power Plants

Plating Operations

EDI Pre-treatment

Food and Beverage |

Spot Free Product Rinse

Cooling Towers

Laboratory

Boiler Feed Water

Ice Manufacturing

Ion Exchange Pre-treatment |

Operation Conditions:

• Max. feed water temperature: 42°C

• Equipment upgrade for TDS up to 5,000 ppm

• Hydrogen Sulfide must be removed

• Max. Silica tolerance: 25 ppm @ 60% recovery

• Feed water TDS: 0-2,000 ppm

• Operating pressure: 150 to 250 psi |

• pH tolerance range: 3-11

• Max. Iron content: 0.05 ppm

• Feed water pressure: 20 to 80 psi

• Hardness over 1 GPG requires water softener

• Turbidity should be removed

• Operate at higher TDS by lowering recovery |